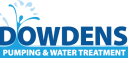

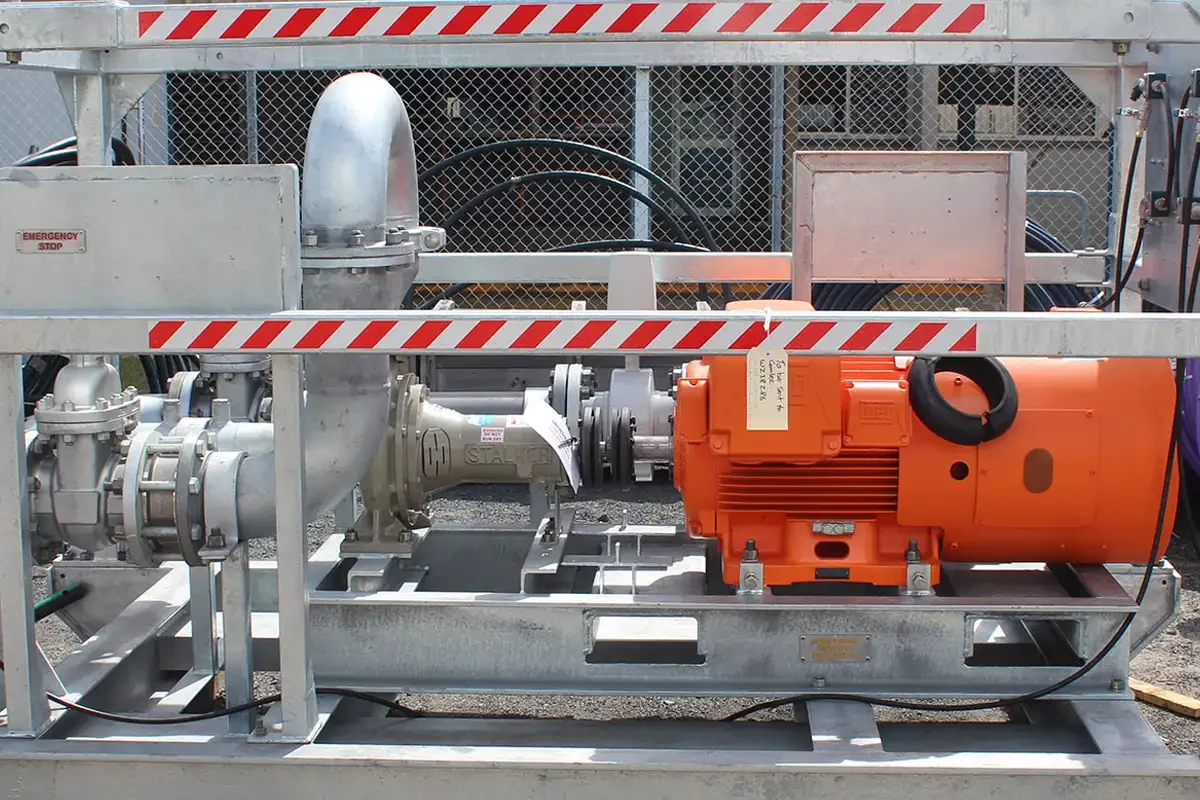

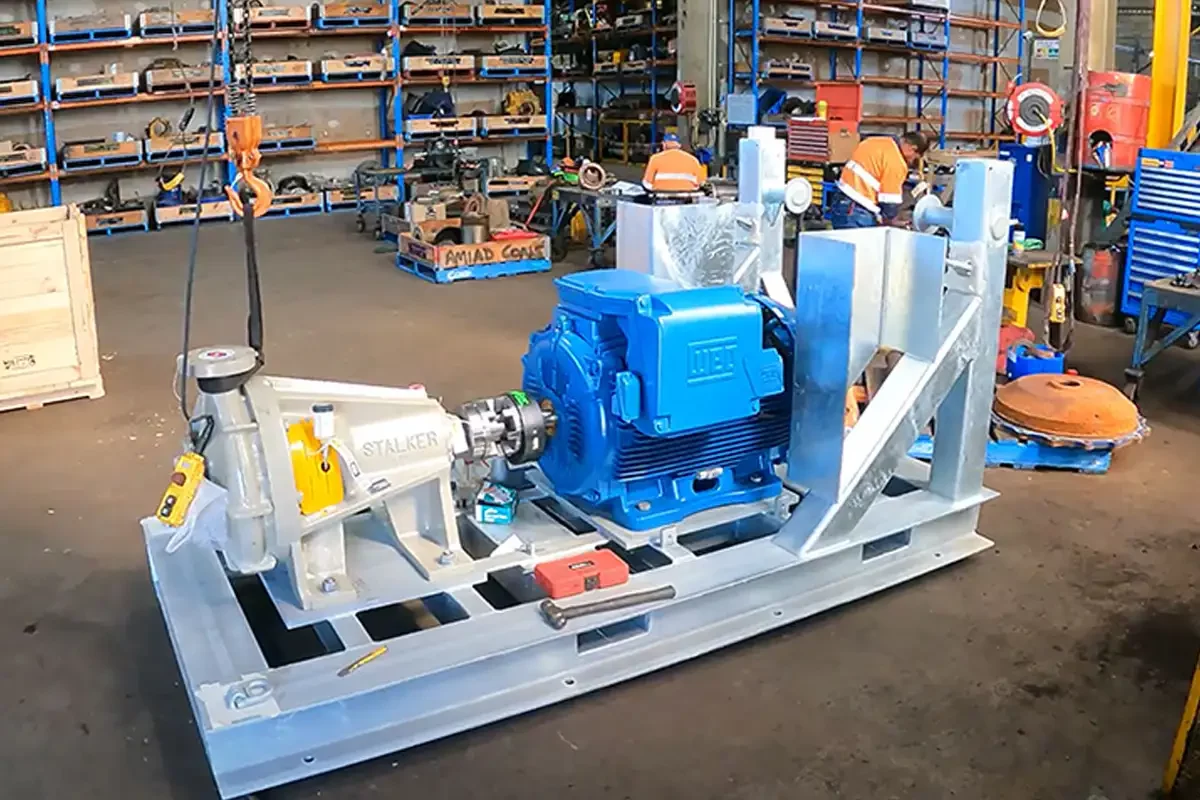

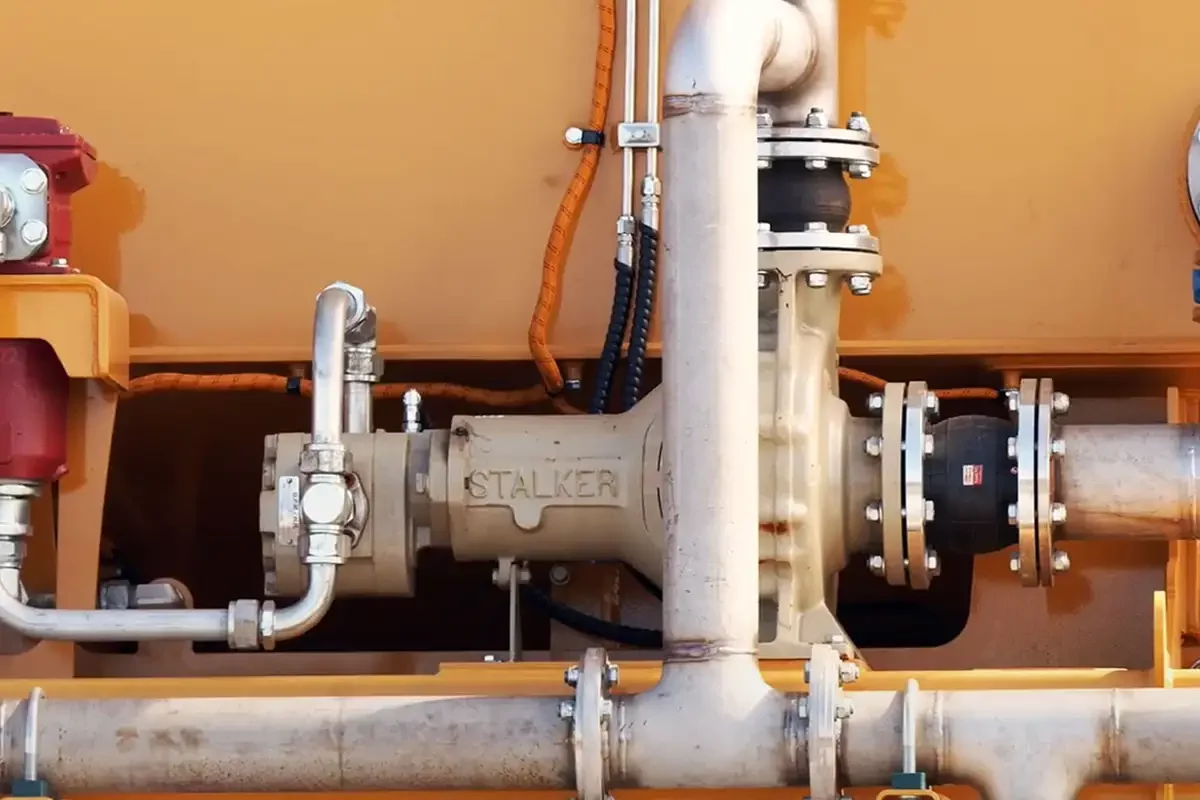

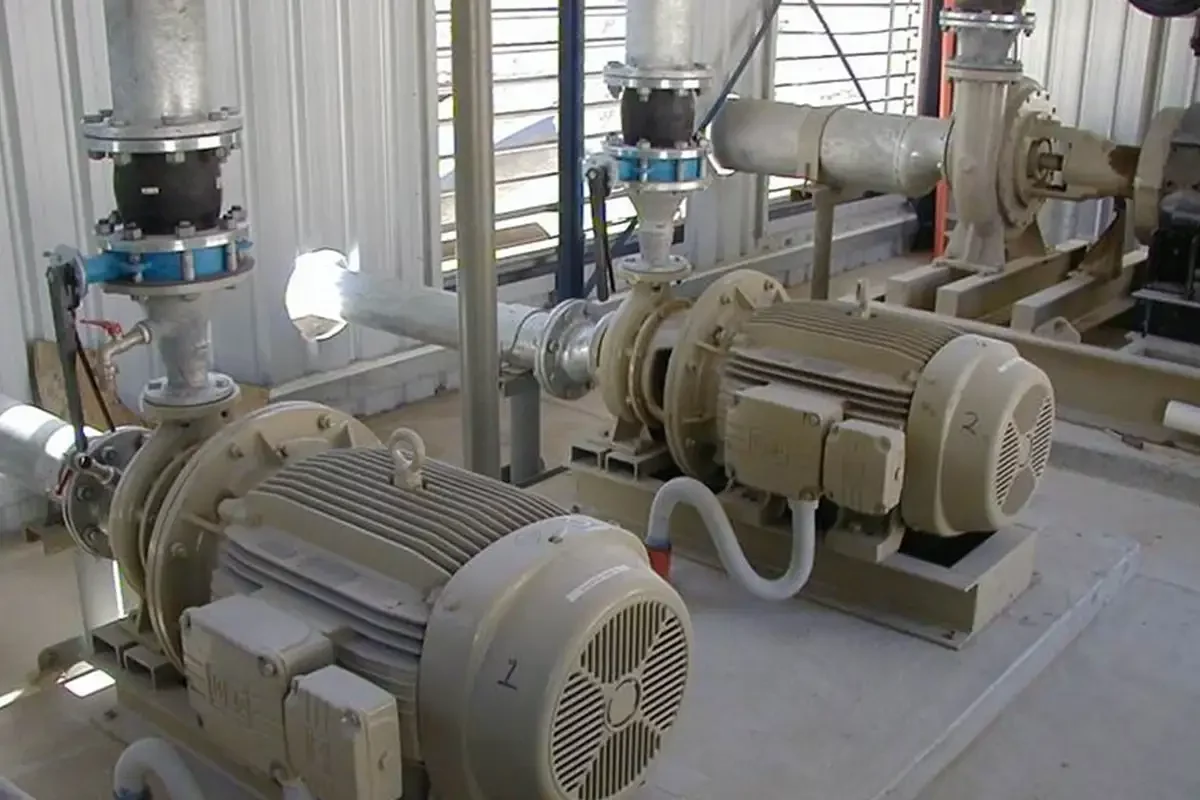

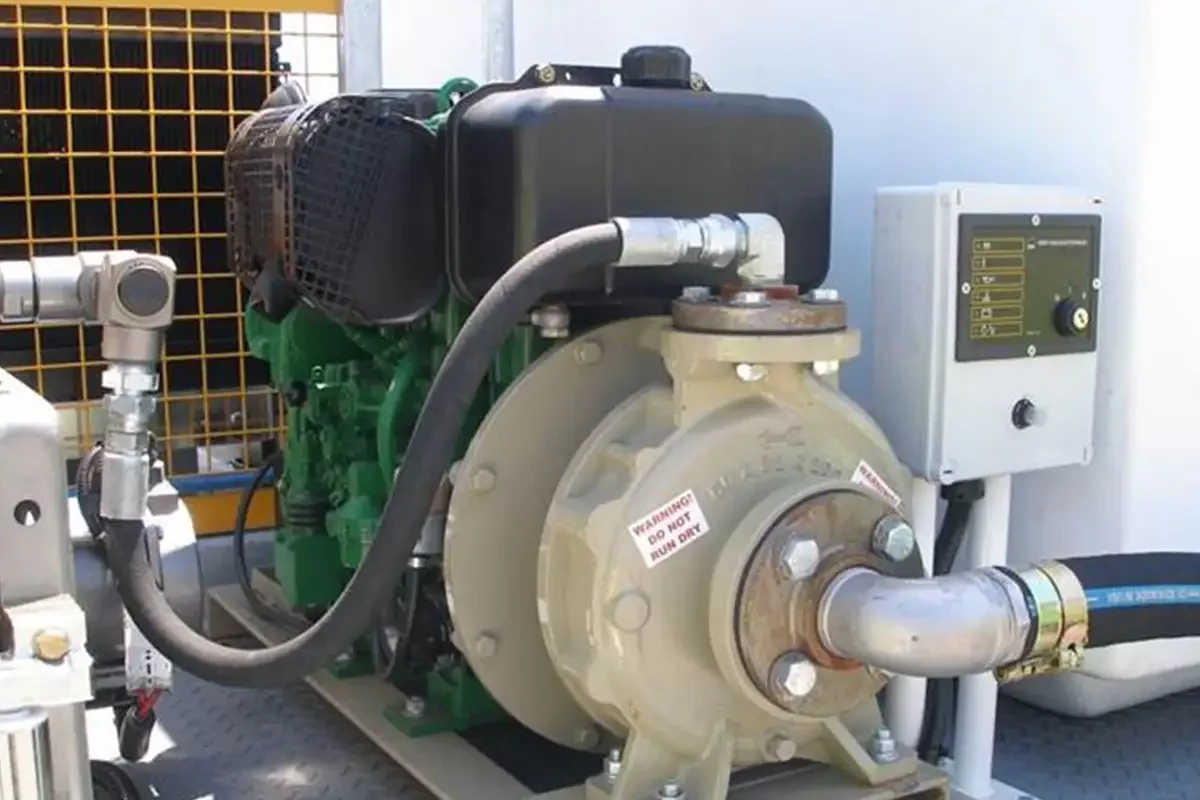

Based in Perth, WA, Stalker Pumps has proudly operated and manufactured pumps since 1923. Stalker Pumps is the only pump supplier in Australia with a foundry on site, giving it complete control of the end-to-end manufacturing process. It manufactures a stocked range of pumps and custom-designed pumps and pumping systems.

The foundry enables them to provide complete flexibility, including manufacturing high-quality castings from customer-supplied patterns. They can also cast pumps in over 19 ferrous and non-ferrous metal types.