Chemical Dosing Systems

What is Chemical Dosing?

Chemical dosing is a crucial process in water and wastewater treatment facilities across Australia. It involves the precise addition of chemicals to water or wastewater to achieve specific treatment objectives, such as disinfection, pH adjustment, coagulation, or odour control.

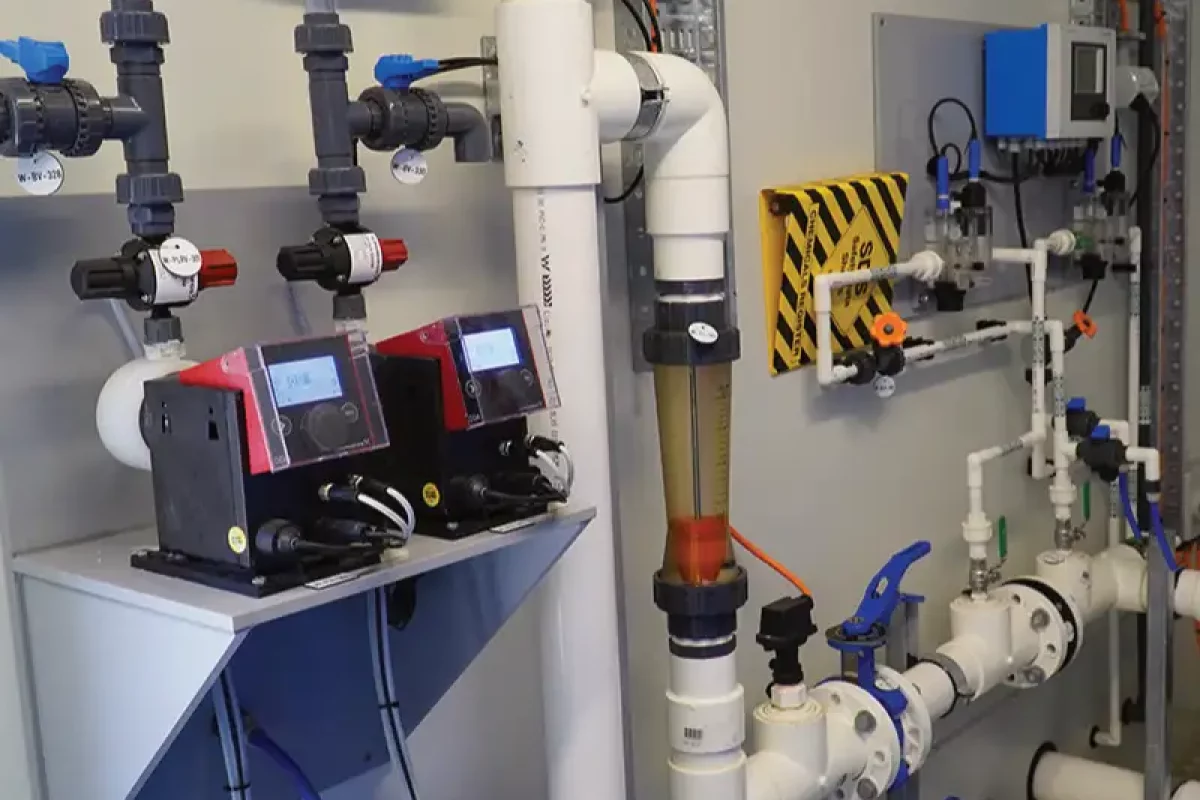

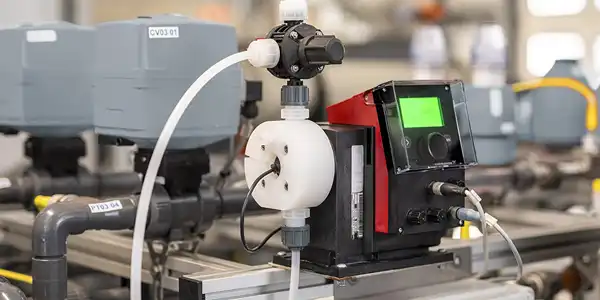

The dosing systems typically consist of storage tanks, dosing pumps, piping, valves, and control equipment designed to accurately deliver the required amount of chemicals to the treatment process.

Chemical dosing facilities are carefully designed and operated to ensure safety, reliability, and effectiveness. They must comply with strict regulations and standards, including those related to hazardous materials handling and environmental protection.

Benefits

- Precision and Accuracy: Chemical dosing systems ensure precise and accurate delivery of chemicals, which is crucial for maintaining consistent water quality and optimising treatment processes. They can automatically adjust dosages in real time based on monitored parameters, eliminating risks of over- or under-dosing.

- Improved Safety: These systems enhance workplace safety by minimising human exposure to hazardous chemicals. They incorporate safety features like automated dosing, leak detection, and emergency shutdown procedures to prevent accidents and spills.

- Cost Efficiency: Chemical dosing systems can lead to significant cost savings over time by optimising chemical usage and reducing waste. They help minimise chemical consumption while maintaining treatment effectiveness.

- Operational Efficiency: Automated dosing systems reduce the need for manual intervention, saving time and labour costs. They can operate continuously and adjust to changing conditions without constant human oversight.

- Compliance and Environmental Protection: Chemical dosing systems help ensure regulatory compliance by maintaining consistent water quality parameters. They also contribute to environmental protection by preventing chemical overdosing that could harm aquatic ecosystems.

These benefits make chemical dosing systems valuable tools for industries requiring precise chemical management, particularly in water and wastewater treatment applications.

Applications

- Water Treatment: Chemical dosing systems are widely used to control pH, disinfect water, and prevent scale and corrosion in both potable and wastewater treatment processes.

- Industrial Processes: These systems are utilised in various manufacturing processes to control the properties of materials, such as viscosity and pH, and to ensure consistent product quality.

- Food and Beverage Industry: In this sector, chemical dosing systems help preserve food, enhance flavour, and maintain nutritional value by adding precise amounts of additives and preservatives.

- Agriculture: Dosing systems are employed for fertiliser injection and pest control in irrigation systems, ensuring optimal plant growth and protection.

- Mining: In mining operations, chemical dosing systems are used for water treatment and to control dust and other environmental factors, thereby enhancing operational efficiency and environmental compliance.

Chemical dosing is used widely across many industries and for a huge range of applications and is not limited to the abovementioned applications. Contact the Dowdens water treatment team for more information.

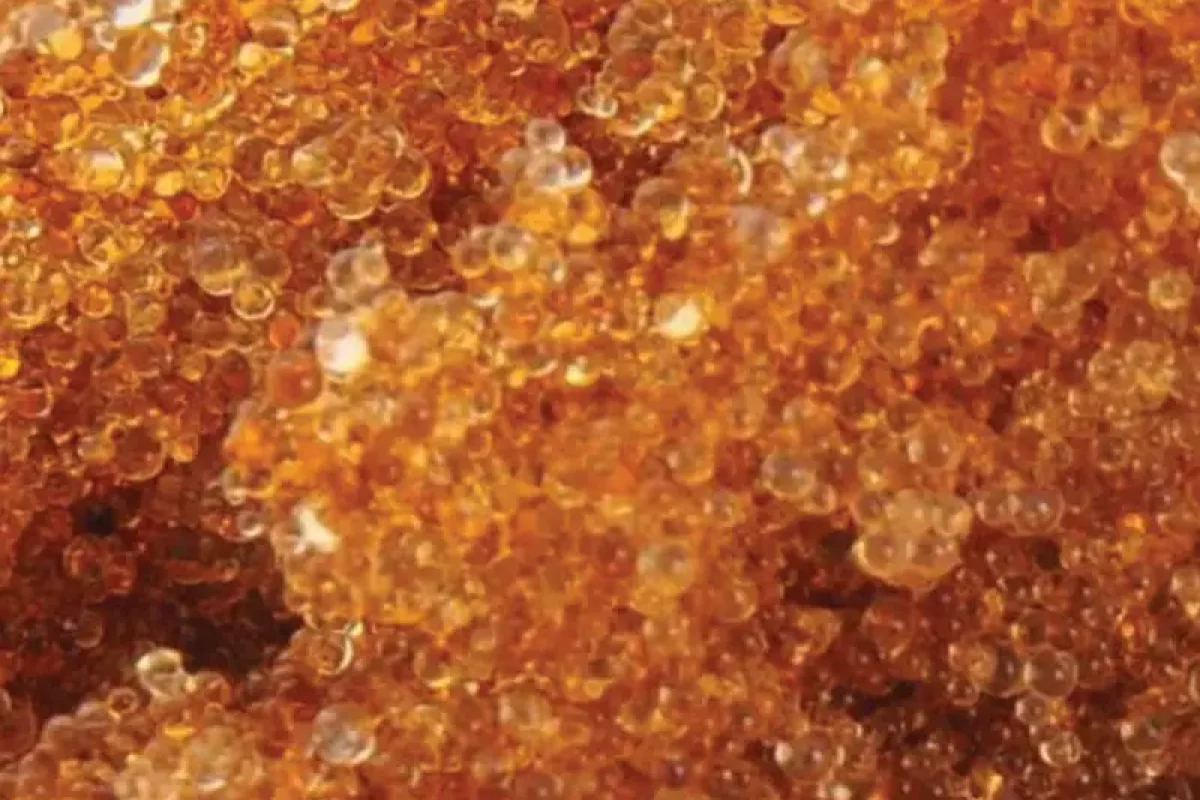

Chemical Dosing Pumps

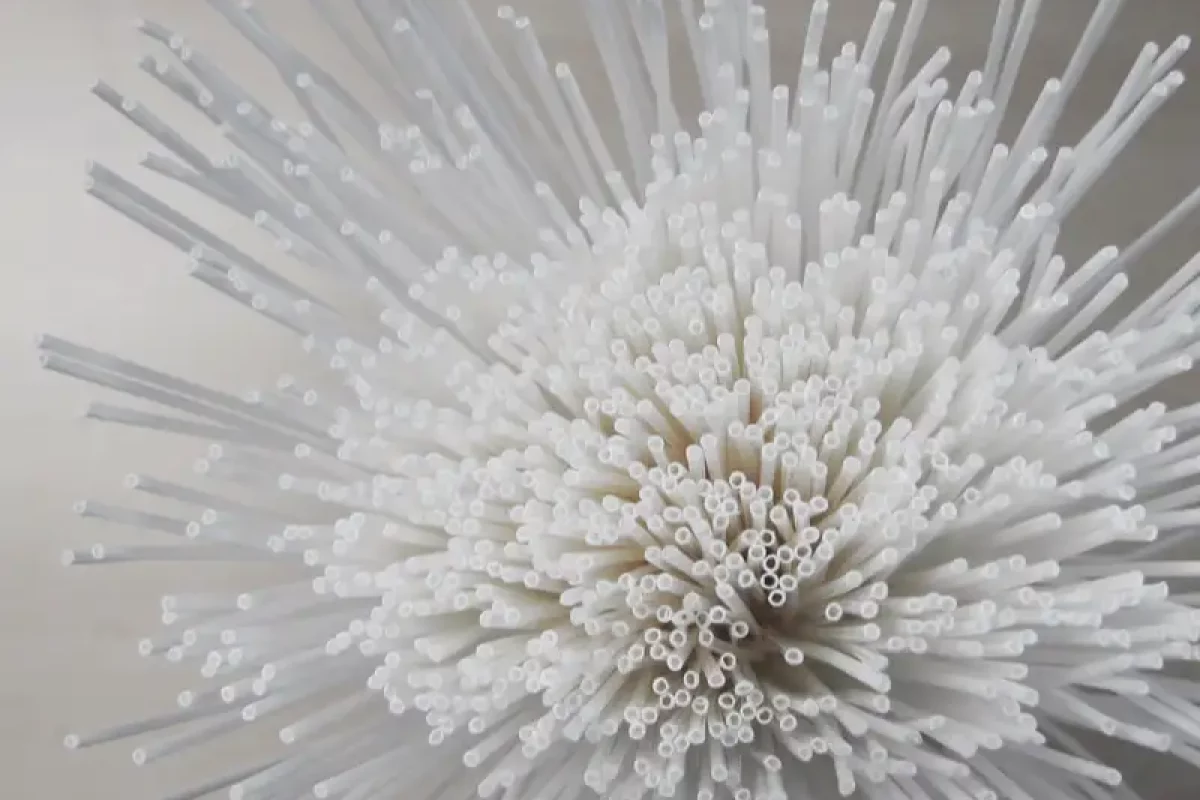

A positive displacement pump, also called a dosing pump, injects a chemical or other material into a flow of water, gas, or steam. Dosing pumps are generally tiny, but they give a very accurate flow rate for optimum control.

They’re the heart of an integrated, automatic dosing system for chemical dispersion. This dosage concept applies to various applications and industries, from wastewater treatment to food processing. Dowden supplies and services the Grundfos range of dosing pumps.

Installations and Components